The vertical pressurized sand filters are used to extract all of the suspended solids and particles sized between

30…60 µm, so-called mechanical impurities.

Filtration under pressure can be carried out in one or more parallel connected filters. Depending on the type of

installation the working pressure of the filter may be from optimal 2 bar to 10 bar or more.

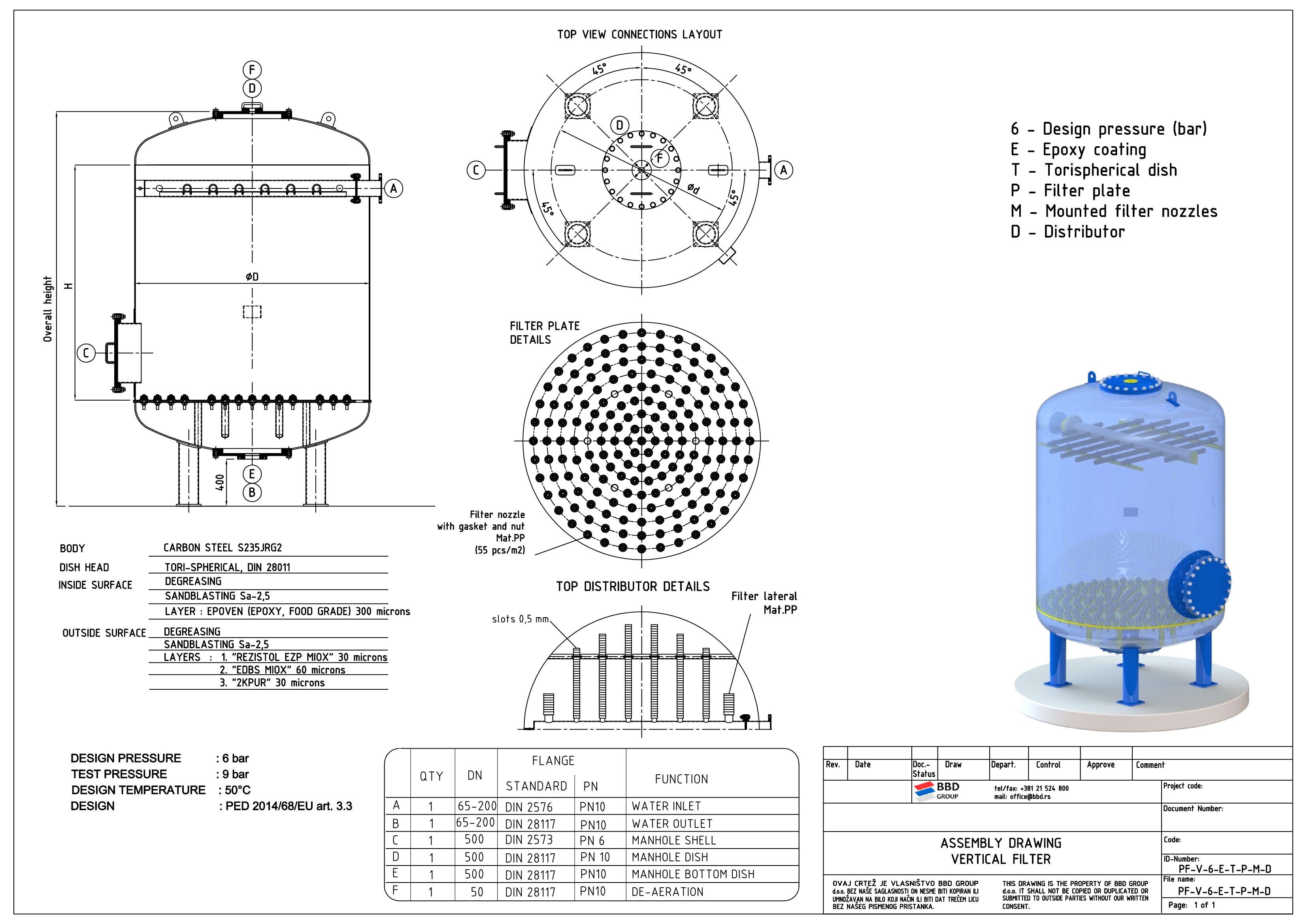

Filters can be made of structural or stainless (AISI 304, 316) steel. Each filter is separately designed for the

thickness of the casing wall and lid, due to the different operating pressure. Corrosion protection is required on

both inside and outside if the filter is made out of structural steel. Corrosion protection is implemented through

sandblasting (SA 2.5) and surface protection with multi-layer epoxy coating. The outer coat consists of a base

and a polyurethane layer with a minimum thickness of 120 µm and the inner coating 300 µm with epoxy coating

approved for use in the food industry.

In addition, of the mentioned surface protection, the inside of the filter can be coated with acid- resistant

"EBONIT" rubber E -10.10. 4 mm thick, with the vulcanization in an autoclave, and after such protection the

filter can be used in installations where aggressive media is used (disinfection of water with ozone or in the

processes in which the filling is regenerated with acids).

It is also possible to make surface protection with processes of cold and hot galvanization.

Depending on the required capacity, the filters can be made in different variants according to the customer's

specification.

| MATERIAL: | CS( S235JRG2) / AISI 304/ AISI 316L |

| EXTERNAL SURFACE PROTECTION: | Sandblasted (SA 2.5) Epoxy layer thickness min 120 μm, 3 layers |

| INTERNAL SURFACE PROTECTION: | Sandblasted (SA 2.5) Epoxy layer, thickness min 300 μm (Food grade epoxy-Drinking water certificate,on request) or Sandblasted (SA 2.5) Ebonit rubber, 4 mm |

| WORK PRESSURE/TEST PRESSURE: | 6 bar / 9 bar |

| WORK TEMPERATURE: | max. 50°C |

| MAX.FLUSHING SPEED: | 30 m/h |

| WATER FLOW SPEED THROUGH PIPES: | max. 2,5 m/s |

| CALCULATION/DOCUMENTATION: | PED 2014/68 CE art 3.3 |

| CONNECTIONS | ||||

|---|---|---|---|---|

| DN | STANDARD | PN | FUNCTION | |

| A | 125 | DIN 2576 | PN10 | WATER INLET |

| B | 125 | DIN 28117 | PN10 | WATER OUTLET |

| C | 500 | DIN 2573 | PN6 | MANHOLE SHELL |

| D | 500 | DIN 28117 | PN10 | MANHOLE DISH |

| E | 500 | DIN 28117 | PN10 | MANHOLE BOTTOM DISH |

| F | 50 | DIN 28117 | PN10 | DE-AERATION |

| G | 50 | DIN 2576 | PN10 | AIR INLET |

Copyright © 2022