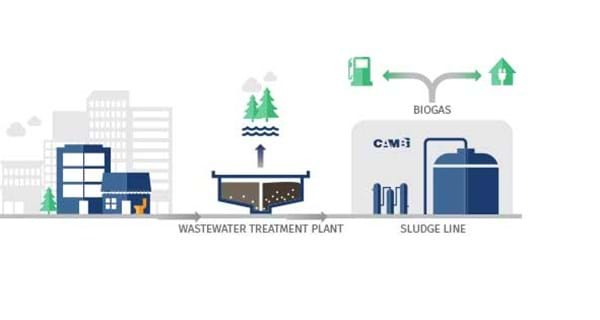

Cambi is the leading global provider of thermal hydrolysis solutions for sewage sludge and organic waste management. Since inventing the thermal hydrolysis process in the early 1990s, Cambi has become a well- known and trusted technology provider for advanced anaerobic digestion and biogas solutions in wastewater treatment.

Cambi’s thermal hydrolysis processes are at the heart of advanced treatment of sewage sludge and bio-degradable waste, whether planning new or upgrading existing wastewater treatment, food waste or co-digestion projects. Conventional problems are reduced, and the material itself becomes a truly valuable resource. Through Cambi’s well tested processes, material and energy recovery is lifted to a whole new level, while minimizing the amount of end-product & maximizing its quality. The results are reduced operational costs and problems turned into products.

The thermal hydrolysis process is best suited for large volumes of homogeneous organic waste. Read more >

The production and quality of the final biomass enables savings in transport and energy - the final product can be directly applied in the agricultural process or dried to be used later as fertilizer or biofuel. In addition to optimizing energy efficiency and reducing operating costs, THP also eliminates the odor problem associated with the processing of organic materials. Cambi's THP plants can be combined with cogeneration plants, which produce "green" electricity and provide hot steam for the thermal hydrolysis (THP) process. Produced biogas can also be used as a fuel in vehicles or as a substitute for natural gas. Cambi offers a wide range of products and services, from basic THP technology to turnkey digestion plants. He also has the skills and expertise to oversee plant operations and maintenance.

Increased biogas production

Thermal hydrolysis enhances biogas production by up to 50%

Improved biosolids dewatering

Thermal hydrolysis reduces the volume of biosolids for disposal

High-quality biosolids

Thermal hydrolysis sterilises the sludge, destroying pathogens

Increased digester throughput

Thermal hydrolysis allows significantly higher loading rates resulting in smaller digestion plants

Lower carbon footprint

Thermal hydrolysis reduces greenhouse gas emissions

Low maintenance, easy to operate

Cambi plants are easy to operate and maintain

Every plant is different. In Cambi, we know this very well and put a lot of

work to customise our value proposition to individual client needs. The goal

is always to maximise our clients' satisfaction over the long run.

We treat a wide range of feedstocks in our thermal hydrolysis systems. We

provide plants in different sizes that are modular, reliable, easy to operate

and low maintenance.

Configurations

Thermal hydrolysis is a process technology that can be applied before, after, or as

an intermediate step of anaerobic digestion.

Cambi can deliver standardised thermal hydrolysis products for a wide range of capacity needs, ranging from 1 500 to 32 000 metric tons dry solids per year, for a single process train. The products take their name from the different cubic meter volumes of the batch reactors: B2, B4, B6 and B12. A process train usually has 2-4 batch reactors, so reactor feeding is uninterrupted.

Copyright © 2022