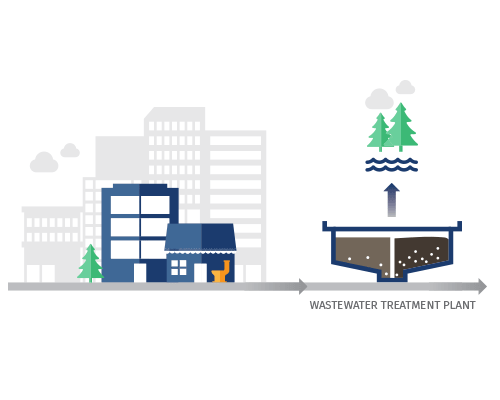

The thermal hydrolysis process is best suited for large volumes of homogeneous organic waste. The most common feedstock is sewage sludge, collected from an urban area to a wastewater treatment plant, through a municipal sewage network. Before returning to nature, the wastewater undergoes a multi-step treatment process to remove organic matter, nutrients and pollutants, in line with local regulations. The first step removes mostly inorganic material, producing primary sludge. Secondary sludge with high organic content is separated in the next step. In some cases, food waste or dewatered sludge may be brought from other locations and mixed with the sludge produced on-site.

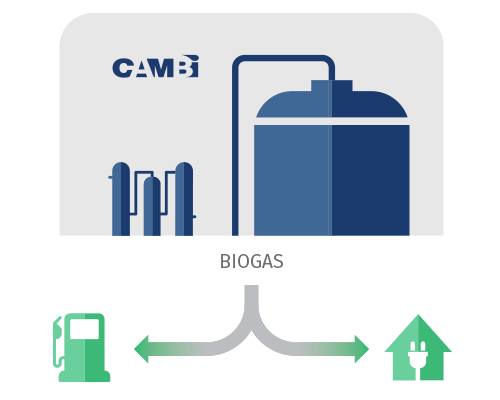

2.A sludge line comprises all sludge processing steps at a wastewater treatment plant. Water utilities invest in many different sludge treatment technologies, to recover energy or nutrients from the sludge, reduce odours, eliminate pathogens or meet other regulatory requirements. Most medium- and large-size wastewater treatment plants recover energy from the sludge via anaerobic digestion. The resulting biogas covers local energy needs or is sold as electricity or natural gas. Thermal hydrolysis is a sludge treatment technology used in conjunction with and improving anaerobic digestion. The sludge line design and sludge management practices often have considerable impact on water utility balance sheets. Cambi makes a difference by optimal integration of our proven thermal hydrolysis process into any sludge line.

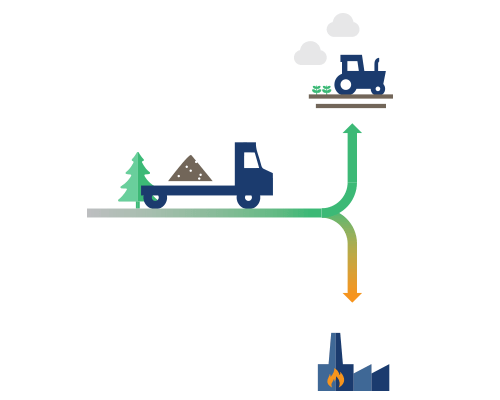

After anaerobic digestion, the sludge is dewatered before final disposal or utilisation. Thermal hydrolysis simplifies sludge management and disposal in several ways: - as biogas production increases, less digestate is left; - final dewatering is less energy-intensive; - the volume of dewatered biosolids is much lower, hence cheaper to handle; - the dewatered biosolids are pathogen-free, low-odour, easy to store and transport. By investing in thermal hydrolysis, water utilities often gain new options for sludge biosolids disposal, such as delivering it to farmers for agriculture. In areas where incineration is required, the resulting biosolids product has higher calorific value, which may translate into lower gate fees.

Copyright © 2022