Ion exchangers are devices used for elimination of salts dissolved in the water, which otherwise cannot

be removed. Their application is in medical, pharmaceutical, laboratory, cosmetic and other

technological processes that require absolutely clean water.

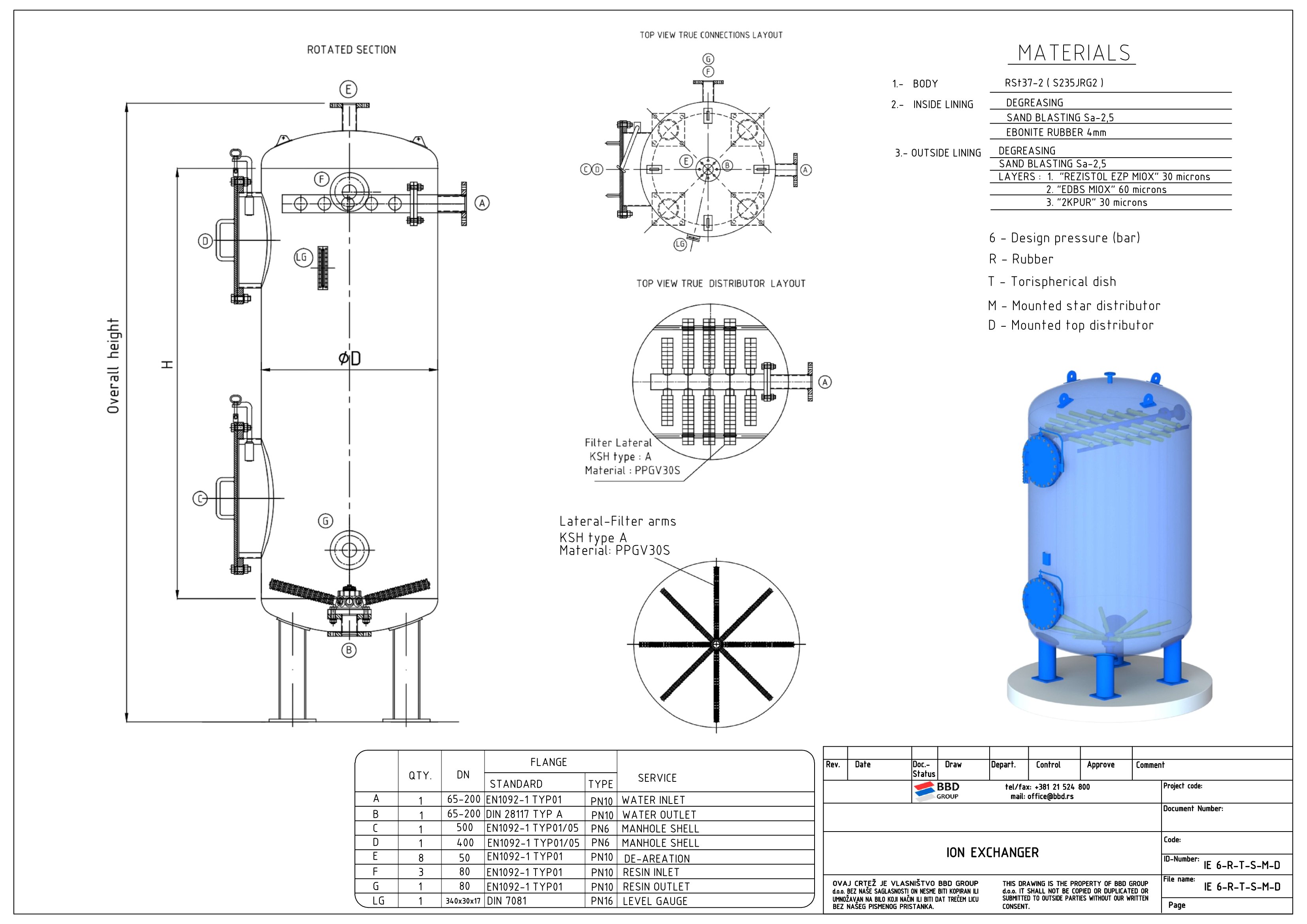

The water softener consists of softener container and container for regenerate. The containers are cylindrical,

vertical, made from steel sheets. A perforated plate with nozzles that retain the ion exchange mass and let by

water is installed in the lower part of the softener container.

In the standard design, ion exchangers have two columns and consist of a cationic and an anionic column,

while the third, "mixed" column, which removes the remaining traces of electrolyte and regulates pH to

neutral, can be added for the obtaining of extremely pure demineralised water.

Demineralized water, in addition to process water in boiler units, is also used for the following:

1. preparation of HVAC water (heating, cooling)

2. production of household chemicals

3. production of drinks (soft drinks, carbonated beverages)

4. laboratories for production of pharmaceutical preparations

5. electrical industry

The quality of raw water at the entrance to demineralizer must be at least equal to the quality of drinking water. If this is

not the case, it is necessary to install the appropriate pre-treatment of water before demineralization

The temperature of incoming water is in the range + 5 °C to + 50 °C, at a working pressure of 6 bar.

The interior container surfaces are protected from corrosion with epoxy coating approved for the food industry or

rubberized ebonite rubber with vulcanization in an autoclave, and the outer surfaces are painted with primary and

final paint.

| MATERIAL: | CS( S235JRG2) / AISI 304/ AISI 316L |

| EXTERNAL SURFACE PROTECTION: | Sandblasted (SA 2.5) Total 120 μm, 3 layers |

| INTERNAL SURFACE PROTECTION: | Sandblasted (SA 2.5) Ebonit Rubber 4mm |

| WORK PRESSURE/TEST PRESSURE: | 6 bar/ 9 bar |

| WORK TEMPERATURE: | max. 50°C |

| MAX.FLUSHING SPEED: | 30 m/h |

| WATER FLOW SPEED THROUGH PIPES: | max. 2,5 m/s |

| CALCULATION/DOCUMENTATION: | PED 2014/68 CE art 3.3 |

| *Other materials and thicknesses are available at the client's request |

| CONNECTIONS | ||||

|---|---|---|---|---|

| DN | STANDARD | PN | FUNCTION | |

| A | 65-200 | EN 1092-1 | PN10 | WATER INLET |

| B | 65-200 | DIN 28117 | PN10 | WATER OUTLET |

| C | 500 | EN 1092-1 | PN6 | MANHOLE SHELL |

| D | 500 | EN 1092-1 | PN6 | MANHOLE BOTTOM DISH |

| E | 50 | EN 1092-1 | PN10 | DE-AERATION |

| F | 80 | EN 1092-1 | PN10 | RESIN INLET |

| G | 80 | EN 1092-1 | PN10 | RESIN OUTLET |

| SG | DIN 28120 | SIGHT GLASS | ||

Copyright © 2022