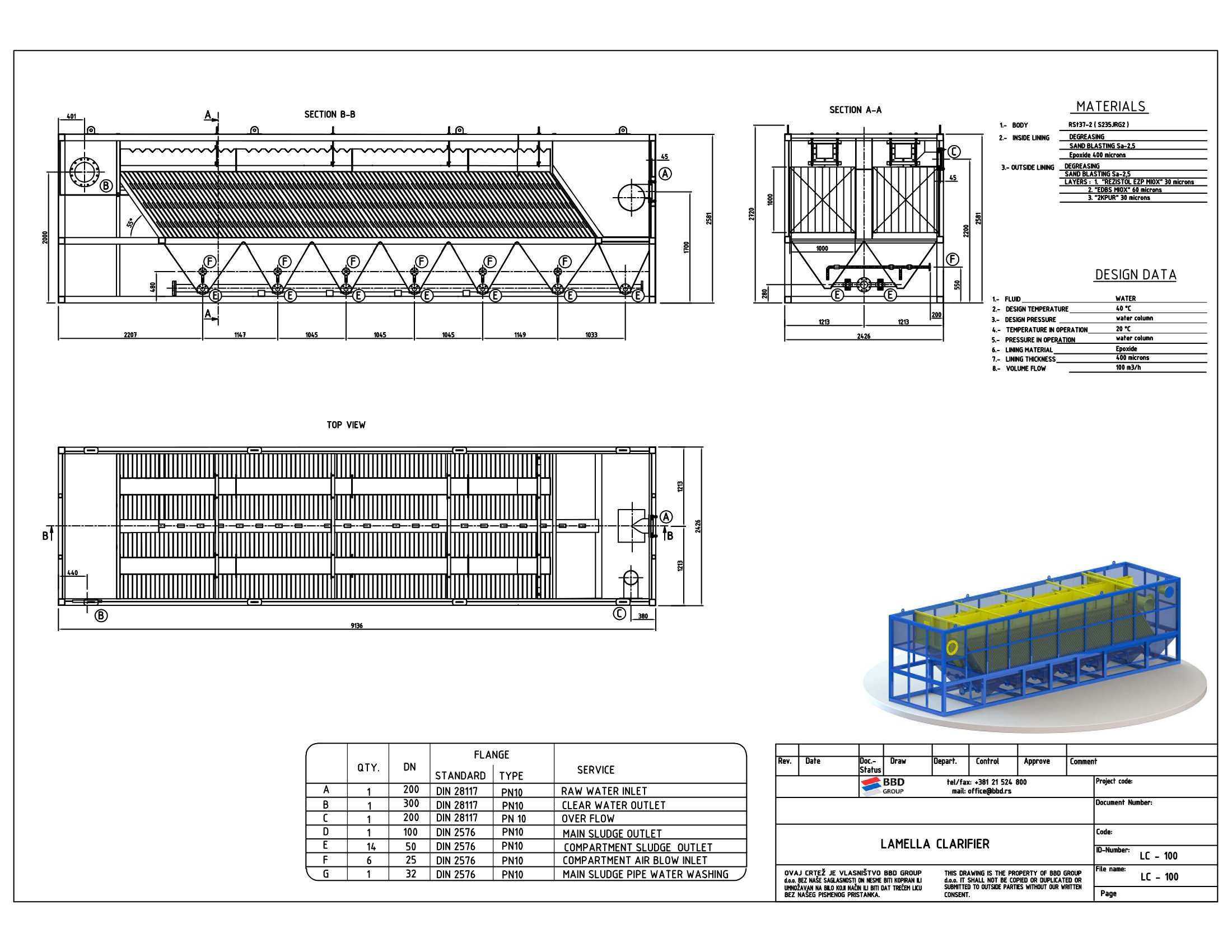

LAMELLA CLARIFIERS

A clarifier is a separator of particles, which is used mainly as a sedimentation device for the

separation of solid particles from the liquid. In addition to the sedimentation of solid particles,

clarifier is also suitable for capturing and removing of floating material. Solid particles with easy

sedimentation are separated and collected in the first (smaller) cone in a large amount, while the rest of the relatively

slow settling particles is separated in the package of plates (or tube settlers) with a cross-flow and collected in the

second cone for sludge. Sediments are thickened and automatically discharged through the drainage pipe.

Clarifiers were created due to the need to bring the efficiency of the sedimentation closer to the theoretically

expected. The retention time of water in the clarifier, which is quite long compared to other stages of water

treatment, should be reduced as much as possible, while achieving the desired degree of sedimentation.

Clarifiers are constructed as pools, in which a system of parallel plates (lamellas) is installed in the form of a bundle,

at a certain angle to the horizontal. The characteristic dimension - distance between the lamellas, is in the range of 2

to 5 cm. Between the installed plates, water loaded with floating particles flows upstream, and releases at that point a

large part of the suspension for a significantly shorter time compared to conventional clarifiers. Optimum hydraulic

parameters are also achieved.

Clarifiers are produced in accordance with customer requests, in a capacity of 8 - 100 m3 / h per unit, most often in

the dimensions of a standard shipping container in order to facilitate their transport to the installation site.