Innovative Aeration Systems for Wastewater Treatment

- Complete aerations systems

- Fine and Coarse Bubble Diffusers

- Membranes and spare parts replacement

- Retrievable system

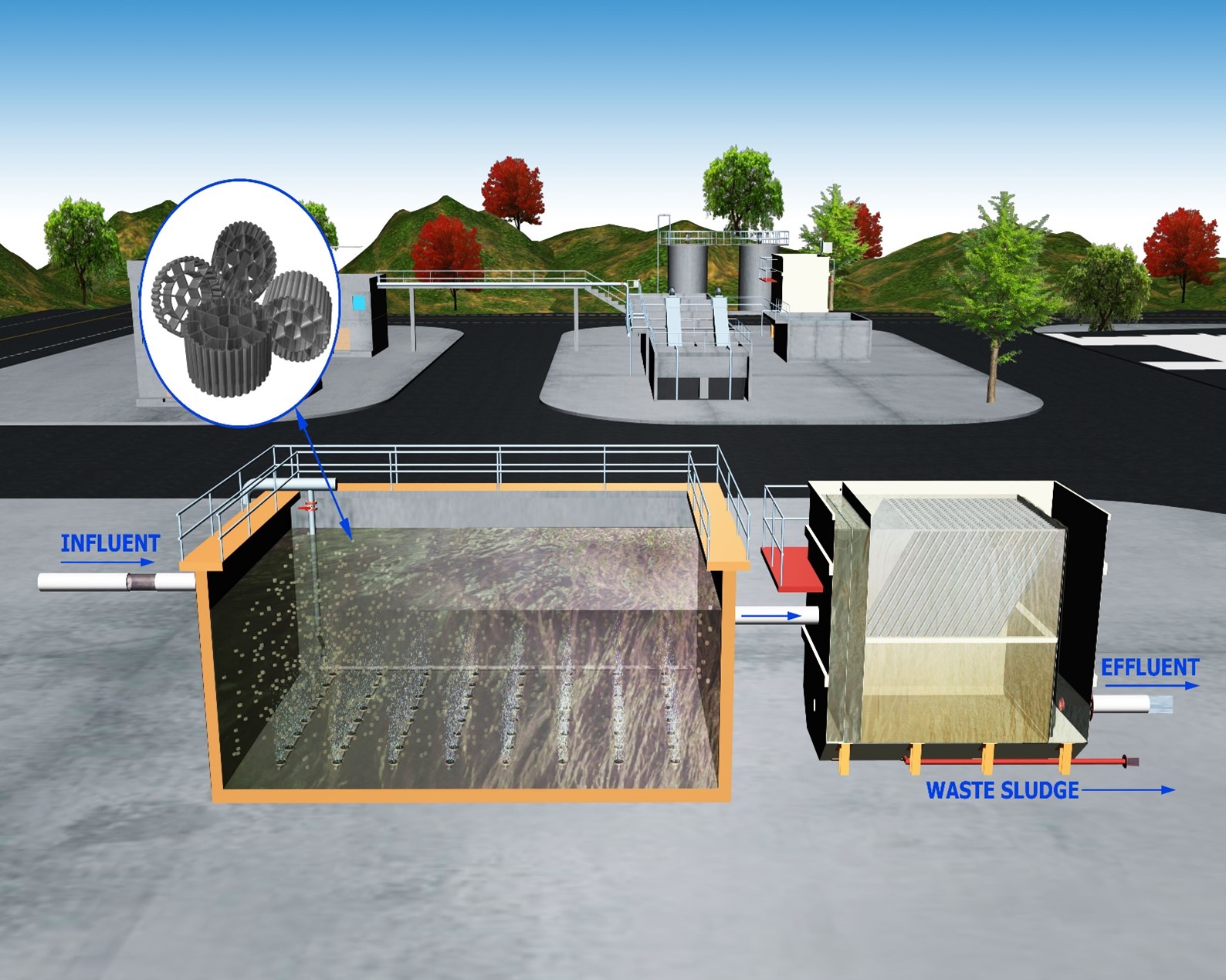

- MBBR Technology

SSI is a global leader in the design and manufacture of wastewater treatment plant equipment. This

includes innovative, robust, and energy-efficient engineered membrane diffusers. These include fine

bubble diffusers, coarse bubble diffusers, and aeration systems. SSI wastewater process division

specializes in the moving bed biofilm reactor (MBBR) and integrated fixed-film activated sludge

(IFAS) processes. Focus is on solutions for both industrial wastewater treatment plants and sewage

treatment plants.

SSI participates in all phases of a wastewater project, from diffused aeration and MBBR system

design, manufacture, supply, installation to startup.

With diffused aeration equipment and complete MBBR’s installed on over 85 countries in 6 continents

at thousands of job sites. We have installed our aeration and wastewater products and systems in

some of the largest cities in the world. Having sold and installed millions of diffusers since the

company was founded, SSI is a trusted source for wastewater treatment solutions.

SSI is bringing diffused aeration into the 21st century for its clients, R & D means iterative

improvements for clients. SSI has aim - to offer high-quality diffusers at a lower price, with the longest

membrane life, significantly faster aeration system installation time and near-zero leaks on startup.

For wastewater applications, careful equipment design and material selection is critical for

successful long-term operation. As an ISO 9001:2015 Quality Certified company, SSI

prioritize quality and strive to produce state-of-the-art complete wastewater treatment plants

and fine bubble and coarse bubble diffused aeration equipment. SSI designs all fine bubble

diffusers, coarse bubble diffusers and MBBR’s to be cost-competitive. In addition, they should

also be easy to install and provide the best efficiency and durability in the marketplace.

Products:

Disc Diffusers

Coarse Bubble Diffusers

Difuzori za grube mehuriće

Fine Bubble Plate Diffusers

Tube Diffusers

Retrofitting

Systems

Digital Pressure(DPMS)

Accessories

A moving bed bioreactor (MBBR) with a smart design can provide better cost-effectiveness than

membrane bioreactor or activated sludge plants. MBBR process design services from SSI Aeration

help wastewater treatment plants improve their efficiency. SSI’s MBBR systems save money in plant

construction, operation, and maintenance.

In secondary wastewater treatment, moving bed biofilm reactor (MBBR) media systems

provide high-quality, low-cost, and low-maintenance solutions.

The EEVolved MBBR from SSI Aeration provides unparalleled results. This proprietary technology involves an innovative biofilm technology for biological treatment. SSI engineers designed the EEVolved MBBR with an advanced understanding of hydrodynamics, aeration integration, and biofilm. As a result, clients receive a treatment process focused on efficiency and safety. EEVolved MBBR systems have the most effective and secure treatment processes available.

SSI systems’ advanced hydrodynamics, aeration, media construction, and biofilm make wastewater processes more efficient, reduce maintenance, and help a facility meet its unique wastewater treatment goals.

On this link you can see how the MBBR technology works

- Energy and operating cost: An MBBR system consumes less energy than other wastewater systems, reducing overall operating costs.

- Reactor volume and HRT: MBBR systems also lower HRT. Thanks to these lower HRT rates, the MBBR can operate in a smaller reactor, saving space.

- Control complexity: Many of the processes involved in MBBR systems rely on microorganisms. As a result, the operator has fewer controls to manage, experiencing a simpler operation.

- Operator intervention: Since an MBBR system requires less complex controls, the operator does not need to intervene as much as they would with another system.

- Treatment efficiency: An MBBR offers better treatment efficiency than other types of wastewater treatment systems at lower space and budget requirements.

- Hydraulic capacity: MBBR systems can handle more water at a given time than other systems, enhancing overall efficiency.

- Volumetric efficiency: With bacteria managing much of the treatment process, the parts in an MBBR system can stay in better condition. As a result, the system optimizes the amount of water flowing through the pumps.

- Process life span: The biofilm media carriers that hold an MBBR system’s bacteria have a long life expectancy. In turn, the system’s process lifespan also increases.

- Compact

- Simple

- Low maintenance

- Flexible

- Efficient

At first glance, IFAS systems may look somewhat similar to moving bed biofilm (or MBBR) processes - both processes use

biofilm growth to help remove organic materials from waste streams, but there are a few key differences between

them.

The right system can improve the treatment capacity of activated sludge treatment systems operating

at or above capacity. Adding an integrated fixed film activated sludge system (or IFAS) can enhance

the capacity and efficiency of an activated sludge system by taking advantage of existing

wastewater treatment technology and boosting it with biological treatment methods. IFAS wastewater

treatment systems provide a variety of benefits to plants using activated sludge treatment systems,

and it’s relatively easy to install an IFAS system at a treatment plant.

In an MBBR system, a biofilm carrier, typically made of plastic or fabric, gets mixed in an aeration

tank with water. The bacteria that accumulate on the biofilm will then break down the organics in the

waste stream and convert them to biomass, which can be extracted from the waste stream later in the

treatment process. This treatment method provides a few different advantages for wastewater

treatment plants — primarily increased treatment capacity at an economical price without much of a

footprint.

IFAS systems do things a bit differently. With IFAS, the biofilm carriers are instead mixed in an

activated sludge basin or combination of activated sludge and water, rather than water alone.

Activated sludge that has already passed through the reaction tank is also recirculated in IFAS

systems. These IFAS systems are often retrofitted onto existing activated sludge systems to take

advantage of existing treatment infrastructure and upgrade conventional activated sludge systems

with tech similar to what’s used in MBBR systems.

Like MBBR systems, these IFAS upgrades can significantly improve treatment capacity without

requiring much extra space — part of why they’re so effective at upgrading existing wastewater

treatment systems. Also like MBBR systems, IFAS systems are commonly used for BOD removal,

nitrification, denitrification and full Biological Nutrient Removal.

IFAS systems often have very high BOD and TSS removal rates — as high as 98.2% and 97.1%,

respectively — making these systems a highly effective means of wastewater treatment.

Copyright © 2022